With the rapid development of the automotive industry, an increasing number of cars are reaching the end of their life cycle. The disposal of waste generated during the automotive dismantling process has become an urgent issue, with particular importance placed on the recycling of plastic waste from steel mill automotive dismantling. In this article, the Wandful Machinery team will guide you through the effectiveness of using an electrostatic plastic sorting machine in the treatment of waste from steel mill automotive dismantling.

I. Application Fields and Challenges of Plastic from Steel Mill Automotive Dismantling

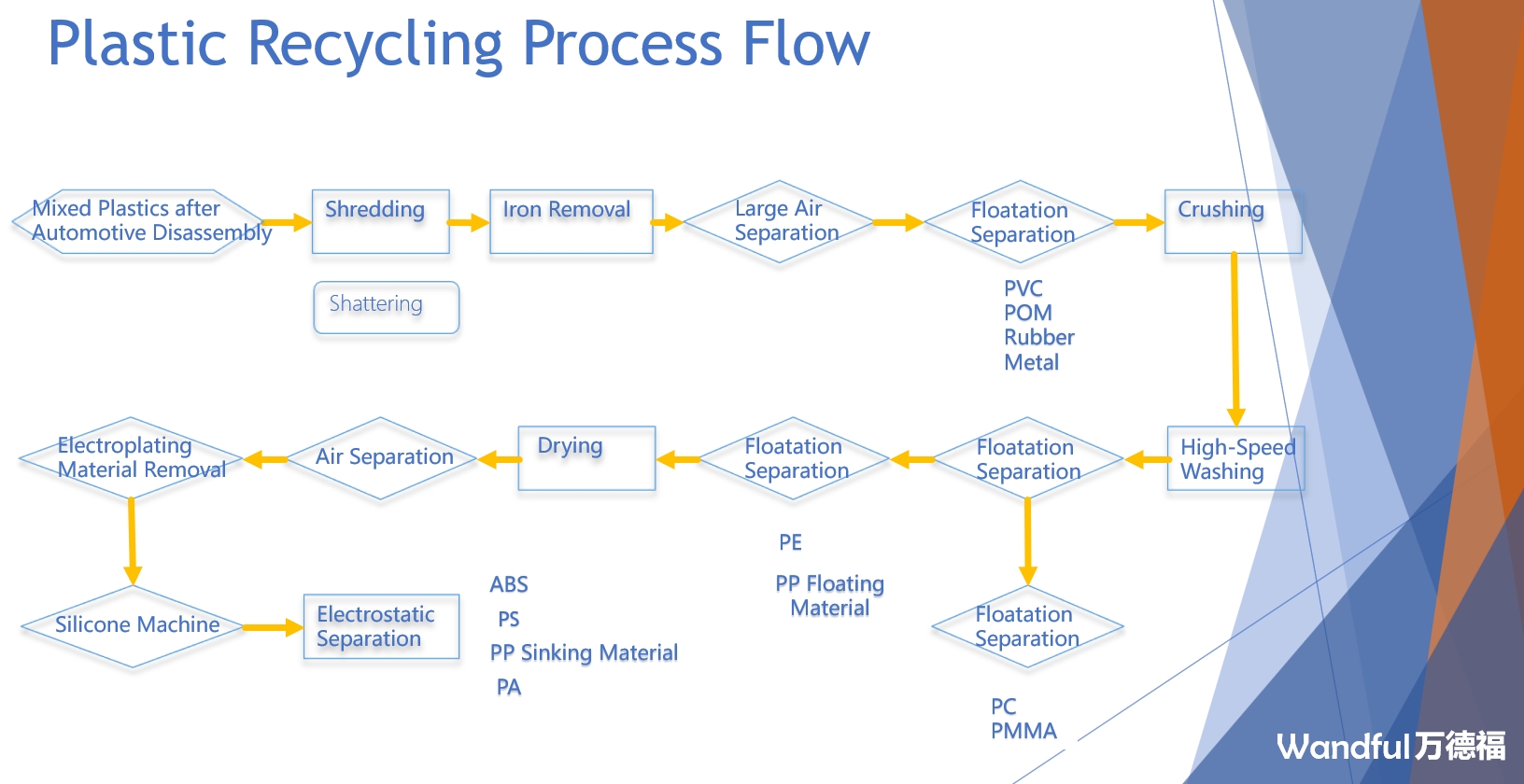

Material Composition: The plastic waste generated during automotive dismantling includes various types such as ABS, PS, PP, PVC, PE, PA, PC, POM, PMMA, and other mixed plastics. Recycling these wastes significantly reduces resource waste, increases the reuse rate of raw materials, and contributes to environmental sustainability.

Sorting Challenges: Due to the diverse types of plastics in waste from steel mill automotive dismantling, traditional sorting methods struggle to accurately and efficiently separate different types of plastic waste, leading to resource waste and secondary environmental pollution.

II. Wandful Plastic Recycling Process and Electrostatic Sorting Features

High Sorting Rate: Wandful's electrostatic plastic sorting machine utilizes the principles of a high-voltage electrostatic field to accurately separate different types of plastics from automotive dismantling. In practical applications, the sorting rate can reach 98-99%, providing high resource recovery benefits.

Environmentally Friendly and Energy-Efficient: Compared to traditional sorting methods, Wandful's electrostatic plastic sorting machine has lower energy consumption and a smaller environmental footprint. It achieves effective environmental protection while increasing resource recovery rates.

Wide Application: Wandful's electrostatic plastic sorting machine can flexibly adjust parameters to meet the sorting requirements of different types of plastic waste from household appliances, making it widely applicable in the treatment of waste from steel mill automotive dismantling.

III. Effects of Using Electrostatic Plastic Sorting Machine on Treatment of Waste from Steel Mill Automotive Dismantling

Increased Resource Utilization: Adopting the electrostatic plastic sorting machine for the treatment of waste from steel mill automotive dismantling achieves high sorting rates and enhances the reuse of raw materials.

Reduced Environmental Burden: Wandful's electrostatic plastic sorting machine, with its low energy consumption and minimal environmental impact, effectively reduces the environmental burden during the waste treatment process.

Economic Benefits for Steel Mills: Recycling plastic resources from waste generated during steel mill automotive dismantling can save costs and create economic benefits for the enterprise.

In conclusion, the use of Wandful's electrostatic plastic sorting machine for the treatment of waste from steel mill automotive dismantling exhibits remarkable efficiency, accuracy, and environmental friendliness. In the future, electrostatic sorting machines are expected to play a more significant role in the field of waste treatment, contributing to the rational use of resources and sustainable environmental development in steel mills.